Today's cars are getting more and more powerful, but still retain the convenient dimensions for the chaotic world we live in. As cars get more demanding, the engine has to do more while trying to hit efficiency targets, thanks to the engine oil we put in to keep the car ticking.

Adverse effects of oil on auto oil seal

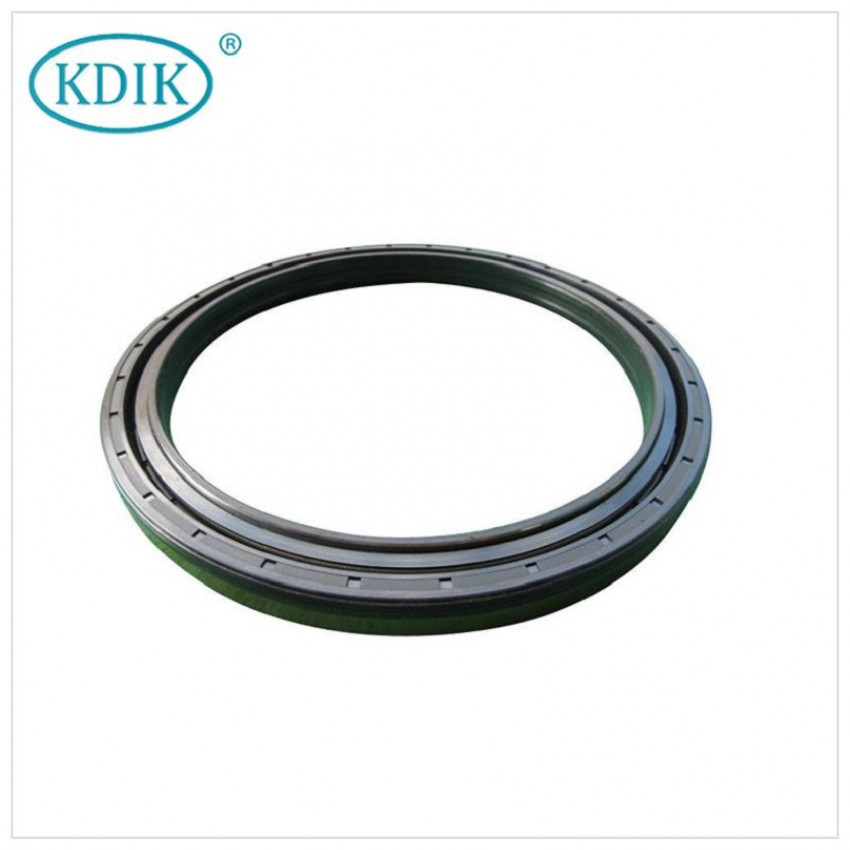

Today's cars are getting more and more powerful, but still retain the convenient dimensions for the chaotic world we live in. As cars get more demanding, the engine has to do more while trying to hit efficiency targets, thanks to the engine oil we put in to keep the car ticking. However, while this oil is good for many components within the engine, it can also cause a lot of damage to components like auto oil seal.

Oil additives are chemical components that improve the lubricating properties of base oils. These additives are essential for proper lubrication and long-term use of engine oils in modern internal combustion engines. Without many of these, oil can become contaminated, break down, leak, or fail to properly protect engine components at all operating temperatures. Some of the most important additives include those for viscosity and lubricity, contamination control, chemical breakdown control, and seal conditioning. The viscosity of oil also varies with temperature, becoming more viscous when cold and more viscous when hot. Therefore, the viscosity of the oil is affected by the weather and engine temperature.

While additives in engine oil are extremely beneficial to most engine components, the additives currently used can adversely affect auto oil seal, often causing them to wear or leak, leading to early repairs to fix the problem. One reason seals can fail due to oil additives is chemical compatibility, which is an issue when changes are made to lubricant formulations. Sometimes additives can cause seal failure even when the base fluid remains the same. However, the effect is not always predictable, as the seals may wear out faster than expected or simply not perform as they should.

Alternatively, the sealing material can decompose when exposed to corrosive fluids. This can happen when an inappropriate sealing material is selected for the application. The use of incompatible materials can lead to chemical attack of oil additives, hydrolysis and/or oxidation of sealing elements. This will result in loss of the seal lip interface, seal durometer softening, and seal expansion and/or contraction. Discoloration of seals is an indicator of chemical corrosion.

There are certain things to look at in order to avoid premature wear of the seals or not behaving as expected. The fluid pressure range needs to be checked, which includes not only the operating range of fluid system pressure, but also the severity and frequency of system pressure spikes.

Another key factor is temperature range, as this will be affected by additives in the engine oil, and possibly engine temperature and even weather. The resting and operating temperature ranges of the fluid and cylinder components are important for seal selection.

Fluid type due to fluid medium and viscosity is important for seal efficiency and effectiveness. Doing this will ensure long oil seal life and reduce the need for early maintenance.

The size of the seal will determine the size of the cylinder. This includes rod and bore size, seal groove size, clearance, overall cylinder length, surface finish specifications and stroke length. How the cylinder is used will affect its lifespan under certain operating conditions. This includes cylinder installation, environmental factors and exposure to harsh conditions.

As engine oil additives are added to engine oils, it becomes increasingly important to ensure that the correct seals are selected, not only for the application but for the operating conditions, and to work well with the additive.