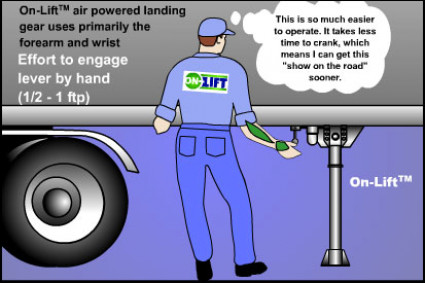

On account of the latest innovations of the On-Lift air-powered landing automated gear for the trailers, authorized by the reliable regulatory authority of Occupational Health & Safety Administration or OSHA, nowadays the shipping companies can offer augmented protection to their truckers against unforeseen health hazards. Such world-class automation eliminates driving-related inaccuracies, thereby preventing muscular-skeletal abrasions and sprains that were previously caused by repetitive cranking of the landing gear.

Therefore, to obtain ease of manoeuvrability and enhance the satisfaction level of the truckers, it would be a sensible approach for the shipment and cargo companies to bring in such unique On-Lift landing technology that will effectively boost up the driver hiring improvement techniques.

By What Approach the On-Lift Landing Mechanism help in employing the Truckers?

Enhanced Occupational Security with Zero Wound and Sprains

Built with live evaluations of cargo loadings, identical to 30,000 cycles with zero malfunctions, the pneumatic On-Lift landing automation comes with augmented protection for the trailers and their drivers. It provides the truckers with ease of manoeuvrability, wherein they can easily raise and lower the landing gear in less than 10 seconds, even though it is fully loaded with consignments of around 70,000 lbs.

Thus, this automation offers significant landing functions, unlike the old repetitive methods of cranking that took 10 to 15 minutes to load or unload. Besides, there is no need for any surplus effort to operate the landing functions, as the emergency brake system distributes the required air power. Again, this automated On-Lift landing gear reduces musculoskeletal injuries and lower back sprains from up to 10% down to zero, thereby creating a safer place for trucking occupations.

Moreover, the On-Lift mechanism for landing can be swiftly installed onboard the trailers within two hours, and provides effortless operability for the truckers in any climatic conditions, resulting in the least road mishaps. In addition, with the automated landing technology, the trailer drivers can park their trailers with 20% more space, wherein they can park five trucks instead of four.

Obtain Women-Centric Truck Designs with Work-Life Synergism

This avant-garde mechanism of On-Lift landing can help the trucking companies to sustain an effective synergy for the truckers, especially the women trailer drivers, wherein custom layouts of flexible heights for foot pedals bring in added safety. Such women-based unique designs will offer greater gratification to the women workforce, and help them to continue with their trucking profession.

Moreover to enhance the security of the truckers, specifically the women manpower, an essential network is created by the women truckers with other women drivers in the shipment routes, so that they can interact, stay alert, and feel relieved in their trucking ventures. Herein, some groups such as Women in Trucking aids in removing impediments in the driving problems of the women trailer drivers.

Maximize Hiring and Performance with Optimal HOS

Such automatic pneumatic On-Lift landing gear aids in synchronizing the trucking ventures through maintaining the hours-of-service (HOS). With stipulations given by the FMCSA or Federal Motor Carrier Safety Administration, the operational hours of trucking have been fixed for the truckers up to 11 hours per day, regardless of gender or age. In this context, such trailer drivers can return to their trucking assignments only after 10 hours of continuous and sufficient downtime. Herein, such layoff can help to boost up their morale and stamina to perform their trucking journeys with heightened efficiency.

Therefore, through such unique automation of landing gear, and strict regulations of working hours, the shipment companies can find optimal savings on the rehiring issues of the truckers by approximately $50,000 annually, helping them to increase their yearly profit by around $100,000. Besides, these consignment agencies can reduce the damages in the trailers significantly by almost $3,700 yearly, while securing nearly $40,000 for any repeated trailer procurements.

Final Verdict

Perceiving these cardinal premiums offered by the On-Lift pneumatic landing gear automation, the trucking agencies need to install such highly effective and secure mechanism onto their trucks, thereby bringing a revolutionary approach in driver hiring improvement, especially for the women truckers.