In the rapidly evolving landscape of engineering and design, the role of cutting-edge technology has become more prominent than ever before. Computer-Aided Engineering, commonly referred to as CAE, stands at the forefront of this technological revolution, enabling engineers and designers to simulate and analyze complex systems with unprecedented precision. This article delves into the realm of CAE software, highlighting its significance, the differentiating factors from CAD and CAM software, and a closer look at Siemens Simcenter 3D CAE simulation software.

Understanding CAE Software: Revolutionizing Engineering Analysis

CAE, an acronym for Computer-Aided Engineering, is a suite of software tools designed to facilitate the engineering analysis and simulation process. It empowers engineers and analysts to predict how a product or system will perform under various conditions without the need for physical prototypes. By leveraging advanced numerical methods, CAE software assists in solving complex engineering problems across diverse industries, such as automotive, aerospace, manufacturing, and more.

The ultimate goal of CAE is to optimize designs, improve product quality, and reduce the time and costs associated with physical testing. This is achieved through the simulation of real-world scenarios, enabling engineers to identify potential flaws, weaknesses, and areas for improvement in their designs.

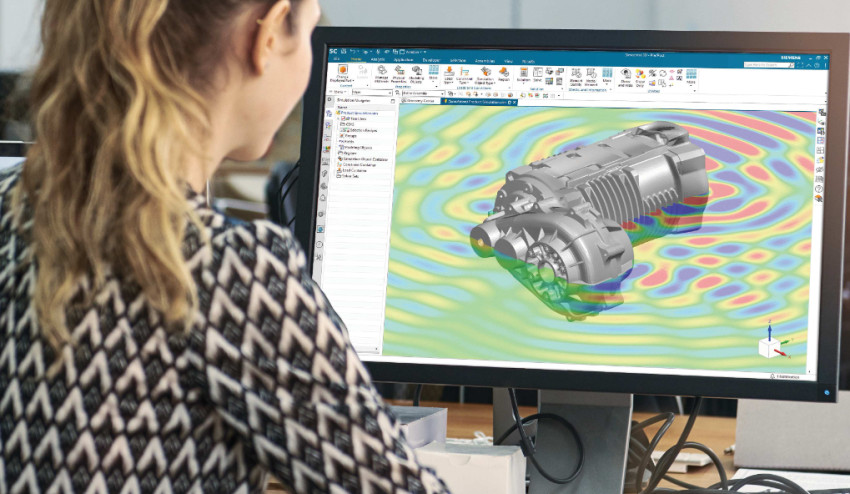

Siemens Simcenter 3D CAE Simulation Software: Redefining Engineering Analysis

When it comes to CAE software, Siemens Simcenter CAE Software stands out as a powerful and comprehensive solution. With its wide range of simulation and analysis capabilities, Simcenter 3D empowers engineers to make informed decisions throughout the product development cycle. From structural analysis to fluid dynamics, thermal simulations to electromagnetic studies, Simcenter 3D offers a versatile toolkit for tackling intricate engineering challenges.

To experience the capabilities of Siemens Simcenter 3D firsthand, you can explore a free CAE software trial offered by Longterm Technology Services. This trial provides an opportunity to navigate the features and tools of Simcenter 3D, enabling you to assess how it aligns with your specific engineering needs.

Distinguishing CAE from CAD and CAM Software: A Clarification

While CAE, CAD, and CAM are all integral components of modern engineering, they serve distinct purposes within the design and manufacturing process.

CAD, or Computer-Aided Design, focuses on creating detailed digital representations of products or systems. It's primarily used for creating 2D and 3D models, serving as the foundation for the physical product.

CAM, on the other hand, stands for Computer-Aided Manufacturing. CAM software is responsible for generating toolpaths and instructions that guide manufacturing machinery in creating physical components based on CAD models.

In essence, CAE software steps in after CAD and CAM in the product development process. While CAD designs the product and CAM manufactures it, CAE simulates and analyzes how the product will behave and perform in real-world conditions.

The Role of a CAE Engineer and CAE Requirements

A CAE engineer plays a crucial role in leveraging CAE software effectively. These engineers are skilled in creating simulations, setting up analyses, interpreting results, and recommending design improvements based on simulation outcomes. Their expertise lies in understanding complex physics, material properties, and engineering principles to accurately model real-world scenarios.

To pursue a career as a CAE engineer, a strong foundation in engineering principles, numerical methods, and software proficiency is essential. A bachelor's or master's degree in engineering, computer science, or a related field is often a requirement. Additionally, hands-on experience with CAE software and an understanding of various simulation techniques are valuable assets.

The Significance of CAE in Organizational Workflow

In an organizational context, a CAE (Computer-Aided Engineering) department or role focuses on integrating engineering simulation into the product development workflow. This ensures that products are thoroughly tested and optimized before reaching the manufacturing stage. By identifying potential issues early in the design process, organizations can save time, reduce costs, and enhance product reliability.

In conclusion, CAE software is a game-changer in the world of engineering, enabling professionals to predict, analyze, and optimize the behavior of products and systems with unparalleled accuracy. Siemens Simcenter 3D CAE simulation software emerges as a standout solution, offering diverse tools for comprehensive engineering analysis. As technology continues to advance, CAE software will likely remain a cornerstone of innovation, shaping the future of product design and development.

To explore the capabilities of Siemens Simcenter 3D CAE simulation software embark on a free CAE Software trial and witness the future of engineering analysis.