In aerospace, all the parts that go into an airplane need to be of the highest safety, performance, and strength standards. Whether one is flying a commercial plane, a cargo plane, or a military fighter, the integrity of each piece counts because lives are at stake. This is where forged parts are important.

Forging is not just a traditional manufacturing process — it’s one of the most reliable ways to make strong, durable, and lightweight parts for the aerospace sector. In this blog, we’ll explore why forged components are essential in aerospace, what types of parts are forged, and how companies like CHW Forge, a leading flange manufacturer in India, contribute to this industry.

Why Forging Is Used in the Aerospace Industry

Aircraft parts experience brutal conditions like high pressure, intense heat, and hard vibrations. They have to resist such forces without weakening. Forging is the best option since it alters the internal framework of metal, increasing its strength and homogeneity.

Below are some main reasons why forging is the choice in aerospace manufacturing:

Strength and Durability:

Forged metals possess a finer grain structure, which provides them with high strength and fatigue capability — well-suited for aircraft components subjected to high stress.

Lightweight Performance:

Aerospace design is always concerned with weight reduction without causing safety concerns. Forged parts enable manufacturers to create light yet powerful parts.

Reliability:

The toughness and consistency of forged parts ensure aircraft safe operation for extended periods of time, even under extreme conditions.

Cost Efficiency in the Long Run:

While forging might cost more to begin with than machining or casting, its longevity and dependability make it cheaper in the long run.

Typical Forged Parts Used in Aerospace

The aerospace industry applies hundreds of forged parts to different systems — engines, landing gear, wings, and structures. Some of the most frequently used forged parts are listed below.

1. Forged Shafts

Forged shafts are one of the key components employed in aircraft transmission systems and engine systems. They convey power from one engine portion to another, maintaining easy functioning and stable operation.

Because they have to withstand high pressure and speed, forged shafts are constructed with high strength and accuracy. They are manufactured with titanium, stainless steel, and nickel alloys to withstand high pressure and temperature.

At CHW Forge, every forged shaft is carefully designed to meet strict aerospace standards, ensuring top-notch reliability and safety.

2. Forged Flanges

Flanges are used to connect pipes, valves, and other equipment in an aircraft’s hydraulic and fuel systems. They play a key role in maintaining leak-free connections under high pressure.

An Indian flange manufacturer such as CHW Forge makes flanges adhering to aerospace quality standards abroad. Cast flanges are not as strong as forged ones and tend to move or shift in stressful conditions like those present around aircraft engines or fuel lines.

Among various flange types, the forged blind flange is widely applied in aerospace industries. It is utilized to close the piping system or vessel's end to ensure safety and to avoid leakage of fluid. These forged blinds are precision-made and pressure-tested to make them safe for high-risk operations.

3. Landing Gear Components

The landing gear supports the complete weight of the plane on takeoff and touchdown. Forged parts like axles, struts, and wheels are employed in this system due to their extraordinary strength and fatigue properties.

Forged steel and titanium are the most prevalent materials for landing gear components. They provide an ideal combination of toughness and weight — a vital consideration in aerospace engineering.

4. Engine and Turbine Parts

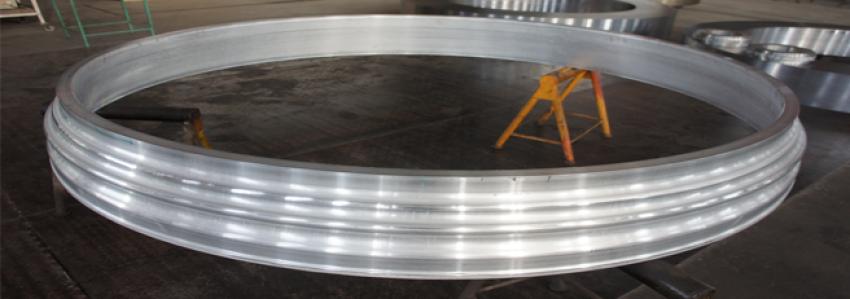

Aerospace engines operate at high pressure and temperature. Components like turbine discs, compressor rings, and blades that are forged are utilized for the engine's safe operation and efficient functioning.

Forged alloys retain their structural strength even at extremely high temperatures. It is due to this reason that engine manufacturers consider forgings for critical parts.

5. Structural Components

The primary framework of an aircraft — the fuselage, wing splices, and brackets — also employs forged components. They aid in evenly distributing stress across the aircraft, enhancing its life and stability.

How CHW Forge Assist the Aerospace Sector

Being one of the top flange manufacturers in India, CHW Forge has earned a robust reputation for providing high-quality forged components for aerospace and other heavy industries.

The firm specializes in manufacturing high-precision components like forged blinds, flanges, rings, and shafts that play a crucial role in commercial as well as defense aviation. CHW Forge employs cutting-edge manufacturing technology, strict quality control, and in-house testing to ensure that each product complies with the world's best standards.

Here's why CHW Forge focuses on excellence:

State-of-the-Art Facilities: Contemporary forging presses and heat treatment equipment guarantee consistent quality.

Material Competence: They work with top-grade alloys such as stainless steel, carbon steel, titanium, and nickel.

Testing & Certification: Each forged component sees meticulous non-destructive testing (NDT), hardness testing, and dimension checking.

Customization: Parts are produced as specified by the client — from selection of material to final machining.

Decades of skill and expertise, CHW Forge is a reliable flange supplier in India catering to Indian and global aerospace customers.

Advantages of Forged Parts in Aerospace

Let us briefly outline why forged parts are unavoidable in this industry:

High Strength-to-Weight Ratio: Necessary for aircraft efficiency.

Uniform Grain Flow: Avoids cracks and weaknesses.

Good Impact Resistance: Captures shock, vibration, and load well.

Better Machinability: Less challenging to develop close tolerances during production.

Greater Reliability: Reduces the possibility of part failure in process.

These advantages directly contribute to the safety and performance of aircraft today, and for this reason, forgings are the preferred choice of aerospace engineers everywhere.

Sustainability in Forging

Aerospace firms today are also becoming more concerned with sustainability. Forging is well suited to the goal since it generates very little waste relative to other metalworking processes.

At CHW Forge, sustainable processes and energy-saving technologies are employed to minimize carbon emissions while ensuring the highest quality of forged components.

Conclusion

The space industry requires the best — and forged pieces provide just that. From forged shafts in engines to forged blinds and flanges in fluid systems, each forged piece helps ensure aircraft safety, reliability, and performance.

With decades of expertise and international acclaim, CHW Forge remains the leading flange manufacturing company in India and among the leading flange suppliers in India for the aerospace industry.

By integrating state-of-the-art technology with talented craftsmanship, CHW Forge is able to provide each piece going airborne with a badge of excellence, strength, and precision.