There are two kinds of wire mesh on the market, namely woven and welded wire mesh. You may be confused: which one is better and how to choose? Here we will introduce what they are, their advantages, and applications. By doing this, you should have a better understanding of which mesh will be more suitable for you.

To properly use them, you must first understand how exactly woven wire mesh and welded wire mesh differ. Failure to understand them can lead to the implementation of the wrong material, and your design will not stand the test of time.

What Is Woven Wire Mesh?

As the name suggests, woven wire mesh is formed when cross wires and line wires are crossed over and under each other. According to the making method, you can find galvanized before woven wire mesh and galvanized after woven wire mesh. The former that the wires used to manufacture the mesh have been galvanized first. That is to say, the material is galvanized wire. While the latter is manufactured, normally in carbon or plain steel, and then be galvanized after woven into mesh.

Advantageous features of woven wire mesh include:

Durable & versatile,

More Flexible & less expensive,

Beautiful appearance,

East installation & low resistance,

Broad availability and customizability.

Woven meshes are flexible and ideal for applications that require odd shapes and contours, such as:

Handicrafts making,

Filtration products,

Insect screens,

Livestock fencing,

wastewater treatment plants,

petrochemical facilities, etc.

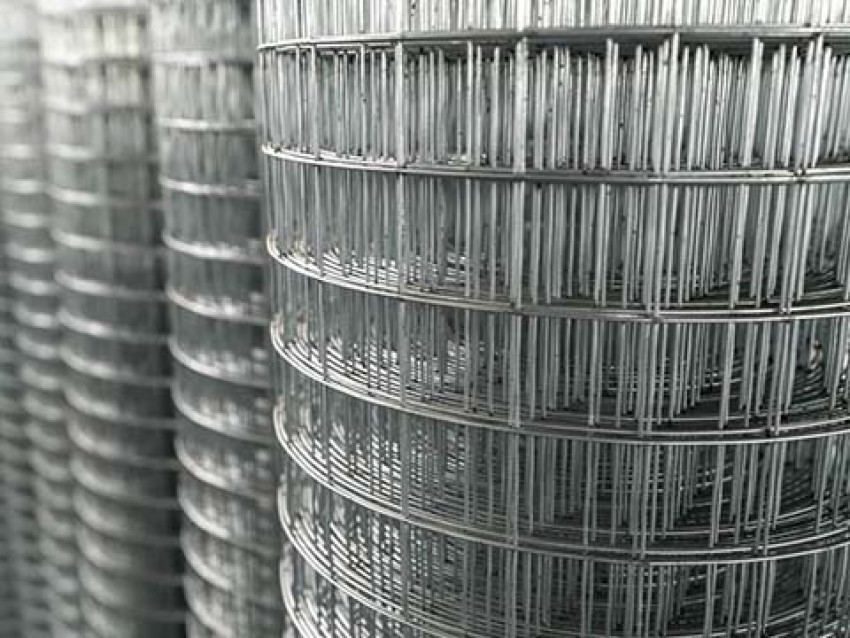

What Is Galvanized Welded Wire Mesh?

Unlike the woven design, the welded wire mesh is typically constructed by welding carbon steel wires or galvanized steel wires together, which then forms numerous welded points. It also has galvanized before welded wire mesh and galvanized after welded wire mesh. Rectangular and square shapes are common in its final designs. What’s more, the biggest characteristic of welded mesh panels is the rigidity that can allow the mesh to bear more weight without deforming.

Advantages that the welded wire mesh carries:

More robust but less flexible,

Good processing performance,

Appealing surface,

Stable & durable,

More expensive than woven one,

Available in stricter specifications and higher degree of precision.

Welded wire mesh is perfect for applications with very high regulatory standards and conditions that could damage a woven mesh. For example:

Reinforcement measures like concrete construction, floor slabs, brick walls, etc,

Machine guards for industrial machinery,

Protective fences like animal fencing, window fencing, door fencing, pet fencing, etc.

Which Kind of Mesh Works Better?

As a matter of fact, both woven and welded wire meshes offer unique and important features for every industry. There’s no way to say which is better. It more depends on what you will use it for.

If you are working with rugged material that requires a mesh that is robust and durable, the welded wire mesh may be a good choice. Instead, if the mesh strength is not an issue and you’re looking for a cost-effective mesh solution, woven wire mesh is much right for you.

How to Choose From Woven and Welded Wire Mesh?

Choosing from woven or welded wire mesh should depend on what it will be used for. As mentioned, welded wire mesh is stronger, but woven wire mesh is more flexible. Woven wire mesh has a finer opening size, so it can be used for filtration, particle analysis, or screen printing applications. Besides, you need to choose according to your budget. The weaving process of woven wire is mostly automated, while the welded mesh is a lot more hands-on. So welded wire mesh will be more expensive.