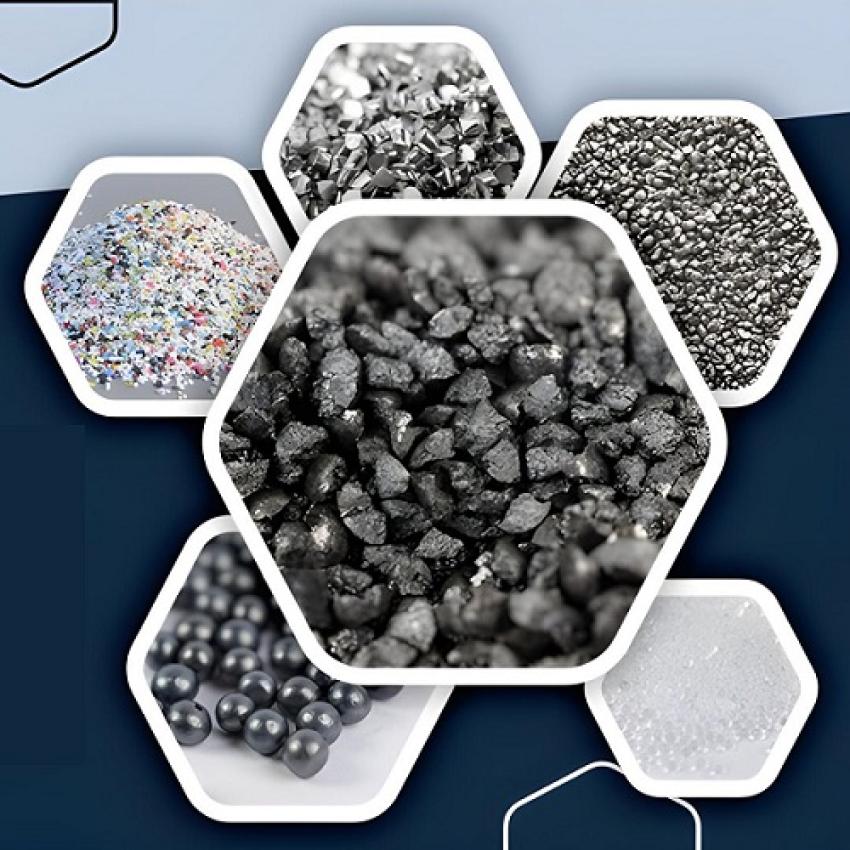

The number of producers and suppliers for the same has increased along with the number of industries. However, they must be of the highest quality and able to depict the appropriate qualities and attributes in order for the industries to use the material. Brown fused alumina is one of the many materials with a wide range of uses. These must be purchased from the top provider of Brown Aluminum Oxide. It is referred to as the teeth in the industry because of its many characteristics.

1. Sandblasting, resin abrasives, water filtration, function filters, and refractory materials are among its applications.

2. Additionally it is employed in the polishing and lapping processes.

3. This important mineral is utilized to make precision casting molds.

Strong compressive ability is linked to it. Its chemical characteristics are stable. Because it is non-toxic and safe, it is an environmentally beneficial mineral. It is cost-effective since it may be used and reused. It has elasticity and hardness as well.

The Reasons of Using Premium Brown Aluminum Oxide in Sandblasting and Different Industrial Purposes

There is no doubt that Premium Brown Aluminum Oxide is used in a number of high pressure industries. Actually this is a very frequent material in these industries. Let us try to know why this is in such a great demand in industries.

Great usage in different industrial purposes

Numerous companies produce high-quality abrasive grains and minerals that are extensively utilized in a variety of construction projects and other endeavors. In an arc furnace that processes alumina as a raw material, white fused aluminum oxide is electrically fused. It is a common alumina grinding medium for blasting, lapping, and polishing.

The primary applications of white fused alumina powder are in the production of refractive materials abrasive tools and various grinding and lapping processes. Similarly brown fused alumina is a crucial component that is utilized for purification and fusion at temperatures above 2200 degrees Celsius in a pouring electric arc furnace.

Able to handle pressure in numerous rigorous processing

It is available in several sizes and qualities. After undergoing numerous rigorous processing steps, it becomes extremely hard, durable, and pure for usage in industrial settings. Applications for brown fused alumina include coating and bonding abrasive tools, sandblasting, lapping and polishing, creating precision casting molds, and other refractory materials.

Another name for pink fused alumina and white aluminum oxide is chromium fused alumina. It offers reduced toughness and high hardness. It is designed to produce abrasive tools that can be used to grind thin-walled, high-carbon, and high-speed steel components. Additionally, the material can be used to precisely grind threading work pieces, machine shift instruments, measuring tools, and apparatus parts.

There are usage for refractory sector

Green silicon carbide and black silicon carbide are the two primary varieties of silicon carbide that are accessible. For processing hard metal alloys and other non-metallic materials like jewelry, eyeglasses, and ceramics, greener materials are best.

It can cut through soft materials like copper, brass, aluminum, and magnesium because of its sharp design. It is applied to abrasive materials like sheets, organic wheels, and vitrified wheels. The refractory sector makes extensive use of it as well.

Good for different high pressure mechanism

Different kinds of abrasive tool material are designed and produced by manufacturing companies. A semi-conductive raw material can be used for wire cutting. One of the primary basic materials made in high-temperature, electric-resistant furnaces is Stainless Steel Shot.

It is a desirable material for creating high-quality abrasive tools because of its strength and durability. So this material is used for a number of high pressure factory purposes. Glass, ceramic, stone, metal, rubber, and other materials can all be processed using this substance.

Guaranteed more precise, quicker, and more effective results

These days, aluminum is a very significant metal that is employed in many different applications worldwide. In actuality, this metal is regarded as beneficial as it is one of the parts of the world that resists corrosion and deterioration accumulations.

In this sense, those involved in the development of metal must develop innovative and high-tech devices that will enable them to expedite and streamline their work. They are guaranteed more precise, quicker, and more effective results at the end of each process with these devices.

Among the several advantages of Brown Aluminum Oxide are the following

- It doesn't require fuel throughout the entire operation.

- Owing to the fact that it works automatically and it is safe for the user's health.

- It permits the elimination of smoking, filth, and pollution-related problems.

- It has an effective rate of reuse.

- Works quickly in fact only ten to 12 minutes to finish the splitting of dross from a 250 to 650kg aluminum.

- Comes as a little economical dedication with a large handling potential and capability.

- Zero pollution is created by this material.

- Low price for production in every industry along with Stainless Steel Shot.

Conclusion

Premium Brown Aluminium Oxide is undoubtedly utilized in a variety of high-pressure sectors. In actuality, these businesses use this material quite frequently. Bauxite is the mineral from which aluminum is derived. The only metals with superior electrical conductivity above aluminum are silver, copper, and gold.

All others have high electrical resistance at ambient temperature. Considering the fact that it’s extremely high thermal conductivity aluminum can be used as a cost-effective alternative to copper. Most probably this is a big reason of choosing Brown Aluminum Oxide in most of the heavy industries.