Introduction: In the world of fasteners, self-tapping screws have gained a reputation for their versatility and ease of use. These unassuming little screws have found their way into numerous applications, from DIY projects to professional construction. In this article, we'll take a closer look at self-tapping screws, answering frequently asked questions to help you better understand these handy fasteners.

FAQ: Frequently Asked Questions About Self-Tapping Screws

1. What Are Self-Tapping Screws?

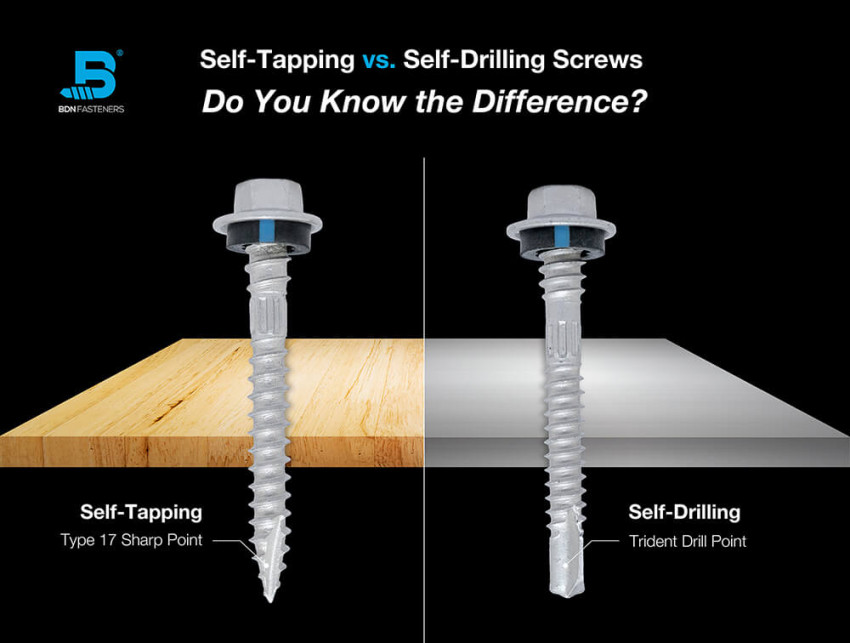

Self-tapping screws are a type of fastener designed to create their own threads as they are driven into a material. Unlike traditional screws that require a pre-drilled hole and a separate nut or tapping tool, self tapping screw feature a unique thread design that allows them to cut and form threads directly into the material, providing a secure and tight connection.

2. How Do Self-Tapping Screws Work?

Self-tapping screws have a sharp, pointed tip and a specially designed thread profile. When you apply rotational force (using a screwdriver, drill, or other tools), the pointed tip helps to create an initial hole in the material. As you continue to turn the screw, the threads on the screw shaft grip the material and pull it tightly against the fastener head, forming a secure connection.

3. What Materials Can Self-Tapping Screws Be Used On?

Self-tapping screws are incredibly versatile and can be used on a wide range of materials, including wood, plastic, metal, and even some composite materials. They are particularly useful for applications where traditional screws would require pre-drilling, making them a popular choice for both professionals and DIY enthusiasts.

4. Are There Different Types of Self-Tapping Screws?

Yes, there are various types of self-tapping screws, each designed for specific applications. Some common types include:

Wood Self-Tapping Screws: These are designed for use in wooden materials and have coarser threads for a secure grip.

Metal Self-Tapping Screws: These screws are intended for metal materials and have finer threads to provide a strong hold.

Plastic Self-Tapping Screws: Designed for use in plastic materials, these screws often have threads optimized for plastic's unique characteristics.

Sheet Metal Self-Tapping Screws: These screws are suitable for thin sheet metal and often have a fine thread pitch for secure fastening.

5. Can Self-Tapping Screws Be Removed and Reused?

In general, self-tapping screws are not designed to be removed and reused multiple times. The act of driving them into the material can cause the threads to deform or strip, making it difficult to re-establish a strong connection. If you need a fastener that can be easily removed and reused, consider using traditional screws with nuts and washers.

6. What Are the Advantages of Self-Tapping Screws?

Self-tapping screws offer several advantages, including:

- Time Savings: They eliminate the need for pre-drilling, saving time on installations.

- Strong Grip: Their unique thread design provides a secure and tight connection.

- Versatility: They can be used on a variety of materials.

- Ease of Use: You don't need special tools to create threaded holes.

7. What Are the Limitations of Self-Tapping Screws?

While self-tapping screws are versatile and efficient, they do have some limitations. These include:

- Material Compatibility: Not all self-tapping screws are suitable for all materials, so choosing the right type is crucial.

- Single-Use: As mentioned earlier, they are not designed for multiple installations and removals.

- Strength in Thick Materials: They may not provide the same level of strength in thicker materials as through-bolts or other fasteners.

8. What Are Some Common Applications for Self-Tapping Screws?

Self-tapping screws are used in a wide range of applications, including:

- Construction: For framing, drywall, roofing, and more.

- Automotive: In the assembly of vehicles and machinery.

- Furniture Making: For assembling wooden or metal furniture.

- DIY Projects: Home improvement and repair tasks.

- Electronics: In the assembly of electronic devices and equipment.

9. How Do I Choose the Right Self-Tapping Screw for My Project?

Selecting the right self-tapping screw involves considering factors such as the material you're working with, the thickness of the material, and the specific application. It's essential to match the screw type, length, and diameter to your project's requirements. When in doubt, consult with a hardware store expert or check the manufacturer's recommendations.

Conclusion:

Self-tapping screws are indeed remarkable fasteners that simplify various construction and assembly tasks. Their ability to create threaded holes in a wide range of materials has made them a favorite among builders and DIY enthusiasts alike. By understanding their characteristics and how to choose the right type, you can ensure a successful and secure fastening in your projects. So, the next time you pick up a self-tapping screw, you'll do so with a deeper appreciation for the ingenuity they bring to the world of fasteners.