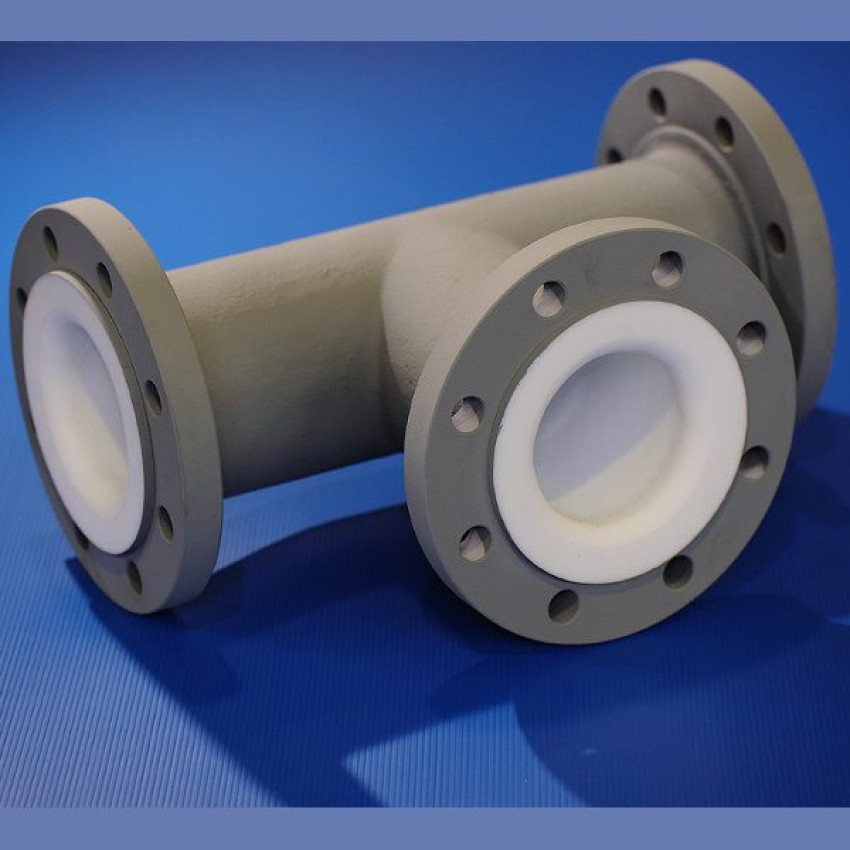

What is Teflon Pipe Fitting?

Pipe fittings connect two ends of a pipe so fluid can pass freely through it, often used inside homes and businesses to prevent leaks or change systems. Plumbers tape (sometimes known as PTFE tape) is widely used by do-it-yourselfers to ensure tight connections and seals on pipes before undertaking projects such as DIY plumbing installations or repairs.

PTFE stands out as an exceptionally durable material resistant to corrosion, making it the ideal material choice for use in various chemical and hazardous environment applications.

When PTFE-lined pipe is unavailable, people often use Teflon tape or pipe dope on threaded ends of their piping systems to ensure a watertight seal. Too many of these products may lead to split fittings; therefore, always ensure at least three standard seal tape wraps around your threaded end for the best results.

Why are Teflon Pipe Fittings a Game-Changer for Corrosion-Resistant Industries?

Chemical manufacturing and handling require companies with highly corrosive liquids to use highly corrosion-resistant pipe material in their pipelines. Otherwise, catastrophic consequences could ensue due to corrosion damage to the environment and their bottom lines. If corrosion causes the failure of one of your pipelines, its failure could have dire environmental and financial repercussions.

Corrosion-resistant pipes require less frequent maintenance, making them the more cost-effective long-term option. Furthermore, they can withstand higher temperatures needed when dealing with certain chemicals.

Plastic-lined pipes, however, were engineered specifically to withstand sudden temperature shifts without dissolving. Their plastic lining protects them from temperature regulation failure allowing liquid within to heat rapidly and expand. At the same time, non-corrosive carbon steel pipes could easily succumb under sudden temperature shifts and overheat and rupture under extreme pressure. Plastic pipes offer greater stability under pressure while being safer to transport than their carbon steel counterparts.

How Does Teflon Pipe Fittings Work?

Today, millions of miles of threaded plastic piping provide safe, reliable service; however, a small percentage can leak or break due to improper assembly of threaded joints. Over-tightening often occurs when subordinates apply too much tape over a threaded or threaded joint.

Teflon tape applied incorrectly can make joints slippery and more likely to over-torque. Furthermore, its incorrect thickness or placement may prevent male-female threads from fully engaging resulting in overload situations.

Teflon tape should be applied to start with its first thread and wrap clockwise around. This ensures that when fittings are threaded into female connectors, Teflon tape remains secure without leakage. Plumber's (PTFE) tape can be found at most hardware stores & supermarkets.

What is the Right Way to Apply Teflon Tape?

Teflon tape can be extremely helpful in sealing pipe threads and making connections easier. However, applying a plumber's tape to achieve an airtight seal can be challenging. It is, therefore, crucial that proper techniques for application be utilized to achieve leak-resistant connections.

Once your pipe threads have been cleaned with an all-purpose cleaner, use PTFE tape in a clockwise direction around its threads until all dirt or grease has been eliminated - making sure the tape overlaps by half its width each time - continuing this procedure three full rotations until complete.

As part of your pipe installation project, it is also essential that you use the appropriate colour of the plumber's tape. White general-use tape works well on standard water lines, while yellow gas line seal tape with grease-free technology can easily seal off gas line seals. Green oxygen lines also benefit from this option which has no unpleasant odours.